Xin Mark Co., Ltd.

Xin Mark Co., Ltd.

No. 258, Gongwu Road,

Longtan District, Taoyuan City

About Us

About Xin Mark

Xin Mark Co., Ltd. was founded by a professional technology team with over 20 years of experience in mold design, mold development, processing through various CNC work station, surface polishing and professional assembly. Xin Mark customize your needs! Our customers may provide samples or offer the ideas of products, Xin Mark brings you extensive structural design expertise to refine mold design, mold developing, and the sample of the product based on your concept and needs. Finally, we make the sample of the product for you to confirm the style and the structure.

To provide the highest quality service, Xin Mark continues to enhance technology and to innovate. Innovation id the wellspring of Xin Mark's growth. At Xin Mark, innovation means more than new ideas, it means putting ideas into practice.At Xin Mark, customers come first. We communicate and collaborate with customers who trust and rely on us to achieve and maintain complete customer satisfaction.

Vision Technology

Xin Mark collaborate closely and responsibly with customers to meet the demand of production efficiency. Our insistency on high quality, diligent, product refining and innovation has successfully opened up the market in Taiwan. Thankful for our customers’ support! Xin Mark has already taken solid steps on Taiwan market and received orders from Thailand, the U.S.A, Argentina and China. We will extend global business with Sustainable Development and Customers Come First policies.

Xin Mark provides molds for various thermoforming machines, including spinning in- mold cutting machines, three workstation production lines and four workstation production lines. We have the capability and experience of developing and designing the best quality molds and have been providing products to ILLIG, GABLER, KIEFEL, WM, TSL, CM, ASANO, CHULING, CHUSONG, SENBA and SUNWELL. Xin Mark specializes in ILLIG series molding and fabrication and achieves the highest quality requirements.

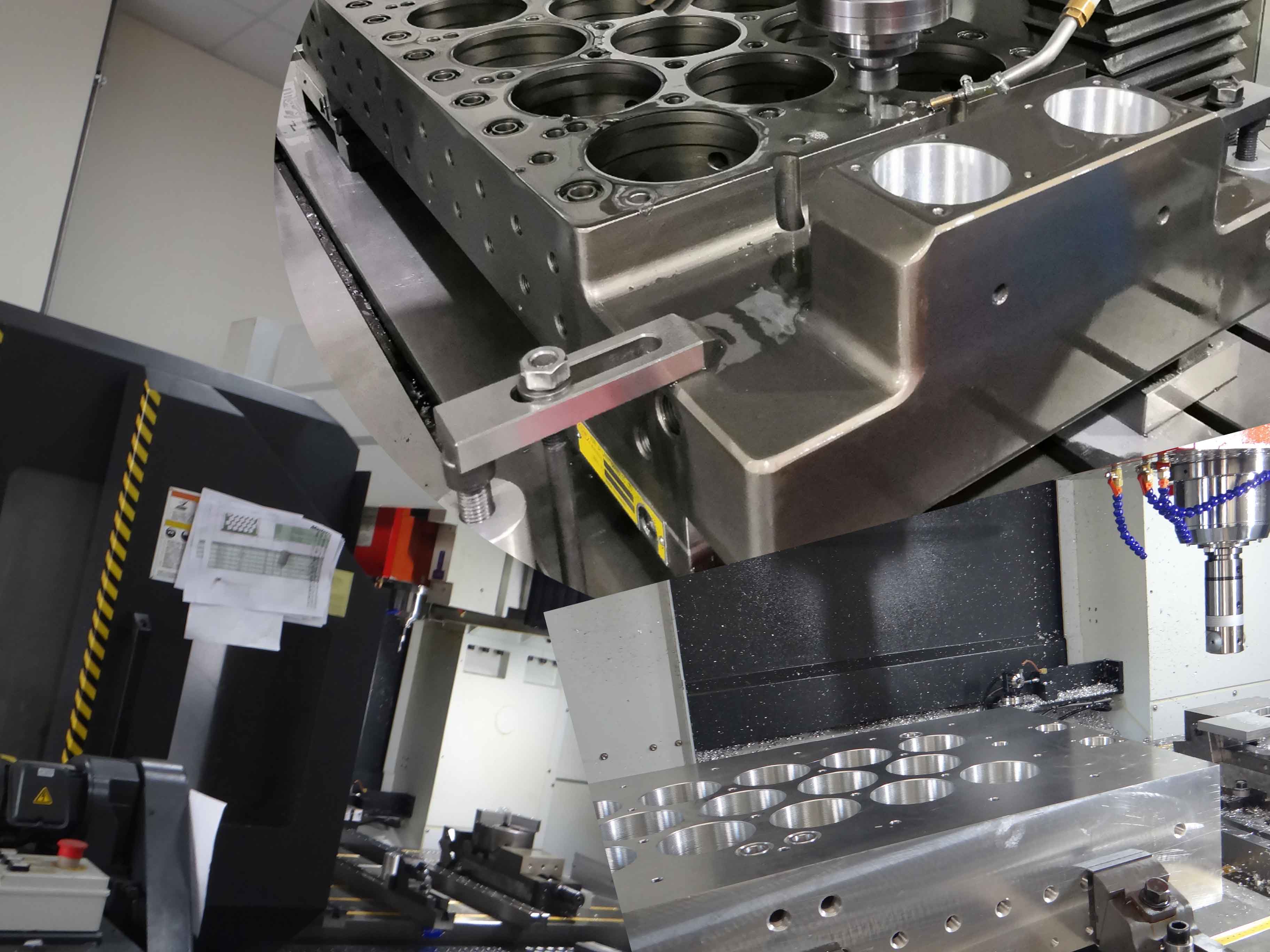

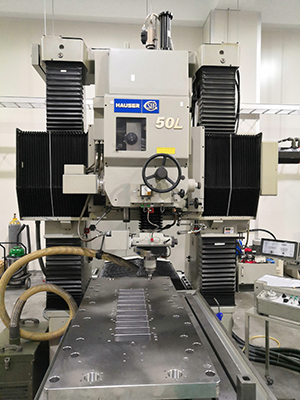

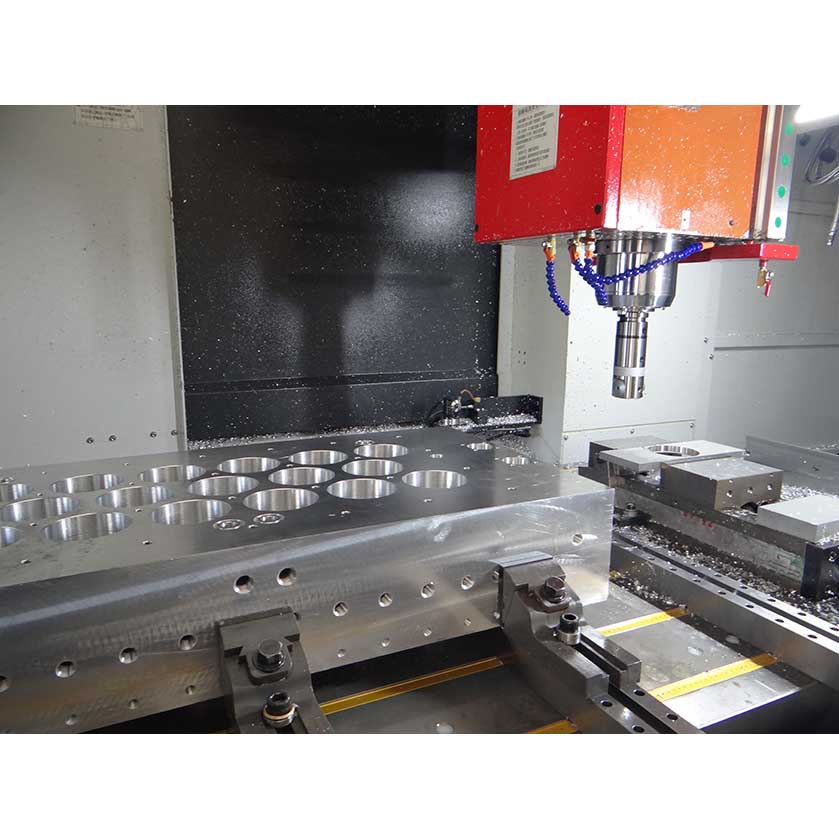

Related Equipment

High-precision three-dimensional measurement equipment

JG coordinate grinding equipment

Knife edge correction equipment01

Knife edge correction equipment02

Knife edge correction equipment03

JG Grinding

JG Grinding-1

Related Videos

Design and manufacture of screw pitch adjustment for crimping screws

75K Trial production image of inverted die cutting machine